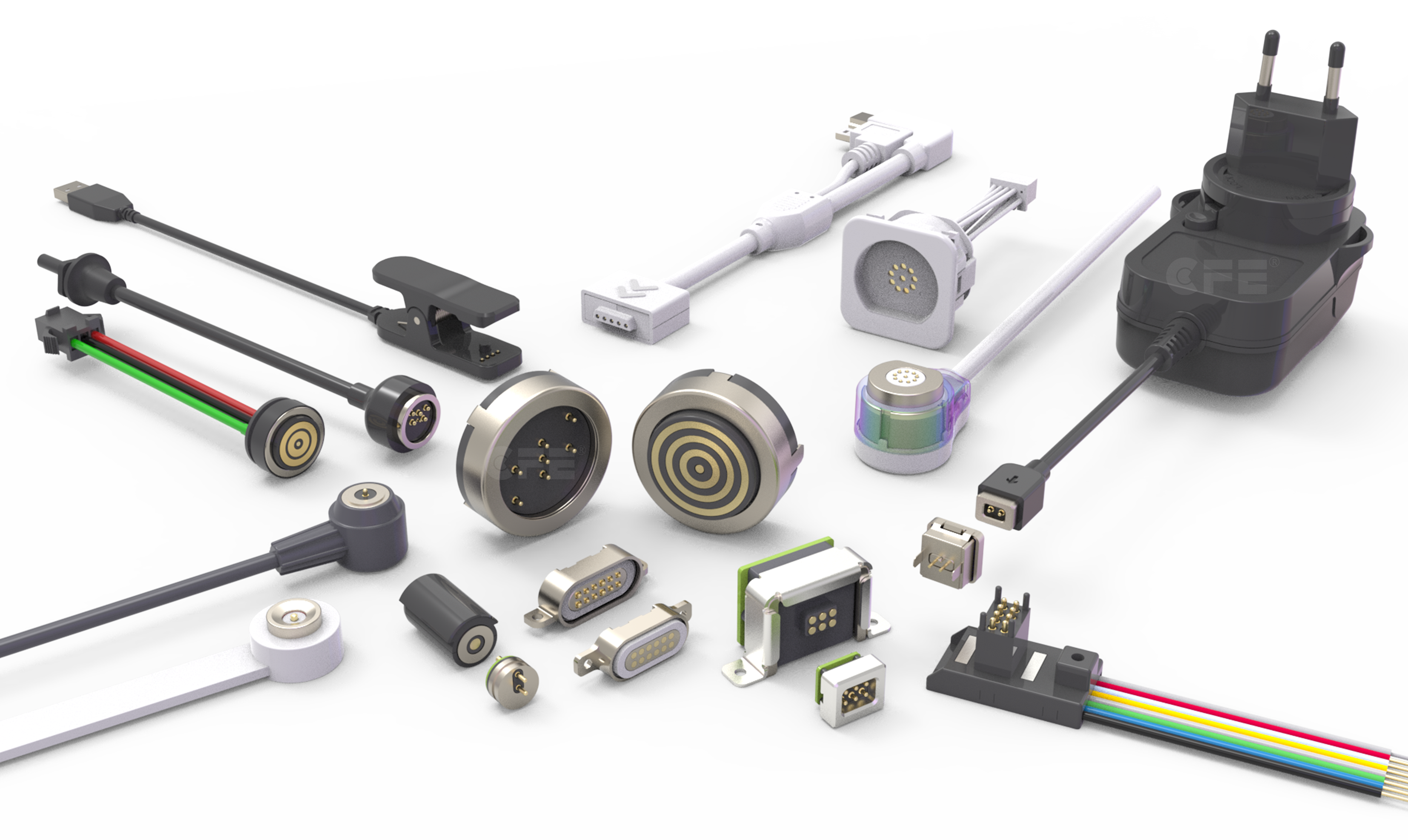

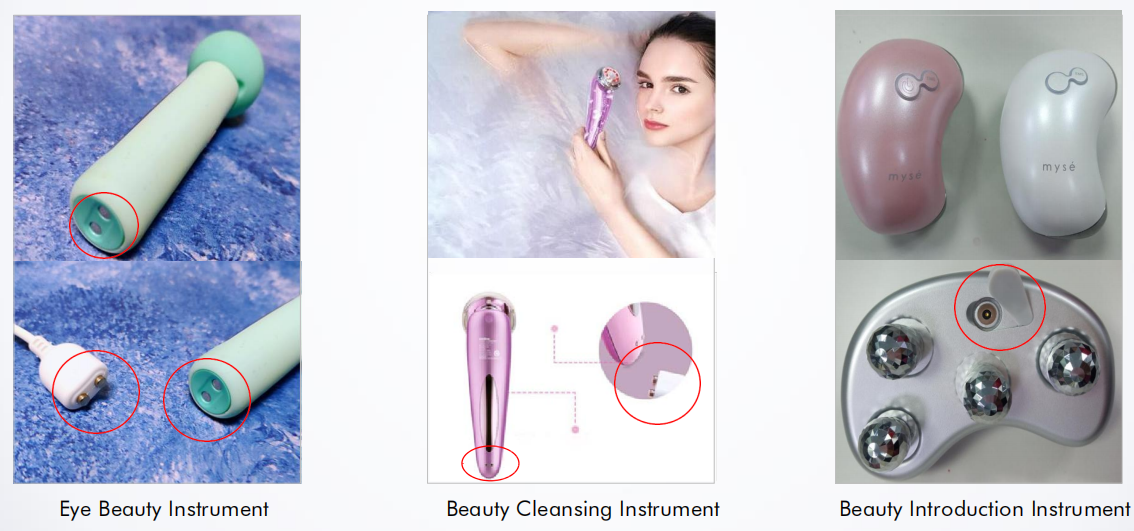

Magnetic cable connector are also called magnetic charging cable、magnetic connector charging cable、magnetic data cable and mainly used in smart wearable、smart robot、 VR equipment、3C digital、smart home、medical equipment、UAV、led industry and so on electronic products to achieve charging、transmission of signals. Magnetic cable connector include pogo pin 、housing、magnet(Fe-Ni alloy)、cable.

Products Structure

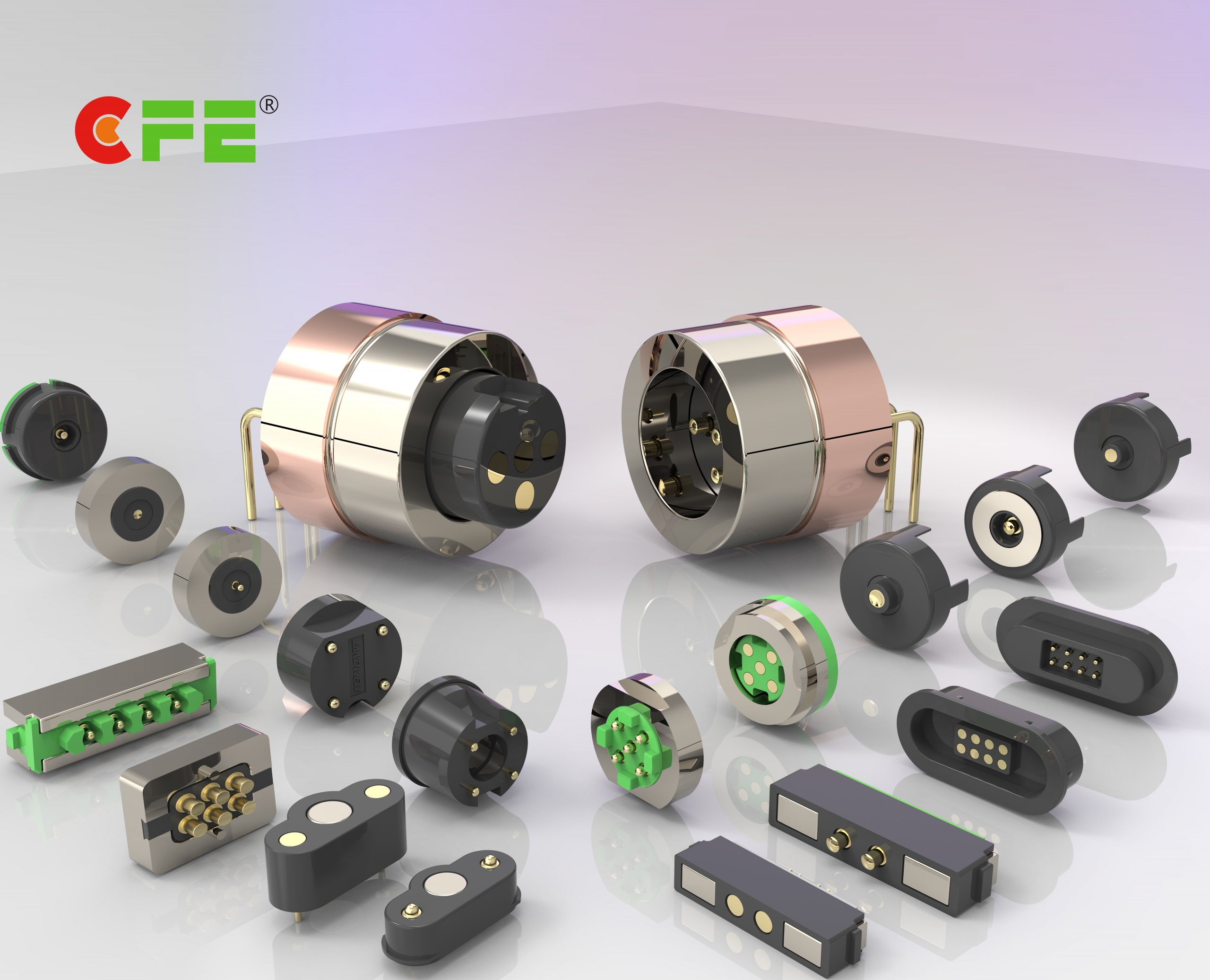

In terms of product structure,magnetic cable connector include the male end component and female end component.Using the principle of magnetic to achieve the effect of adsorption. Magnetic cable connector is easy to use during the process,a magnet is fixed on the top and a magnetic material fixed on the other end,as long as the tow ends are close to each other, adsorption can be achieved. At present, according to different products and structures of charging, magnetic charging cable of various structures have been developed on the market. For example,round structure、square structure、long strip structure、special shaped structure,etc.Adsorption type magnet-magnet,magnet-alloy,magnet-iron selected to solve the problem of meeting the requirement of different structural ends for magnetic field, using NdFeB (permanent magnet) material, the magnetic force will never decay.

|

|

|---|---|

| High quality magnetic pogo pin connector for LED strips | Magnetic laptop charger cable connector with 2 pin |

Function Characteristic

The main expression:

Anti-fall:Uses a magnetic interface to remove the device easier;

Long life:Up to 100,000~200,000 cycles and more function connection charging;

Waterproof design:You can achieve excellent waterproof design, the host female can achieve dust-proof and waterproof (IPX8)

Fast charging:Support a high current (5A-30A)design; fast charging,with less operating time;

Spare saving: The female with PCB adapter can reach Pogo style and SMT DIP bonding jumper connection;

Customized: Diversified shapes and styles, to meet the shape matching of the host product, improve product quality selling points;

Magnet positioning:Use of magnets and structure to dual circuit protection reach distinguish;

Environmental requirements:Excellent corrosion rating (48H-120H) meet the harsh environments.

For more related post: