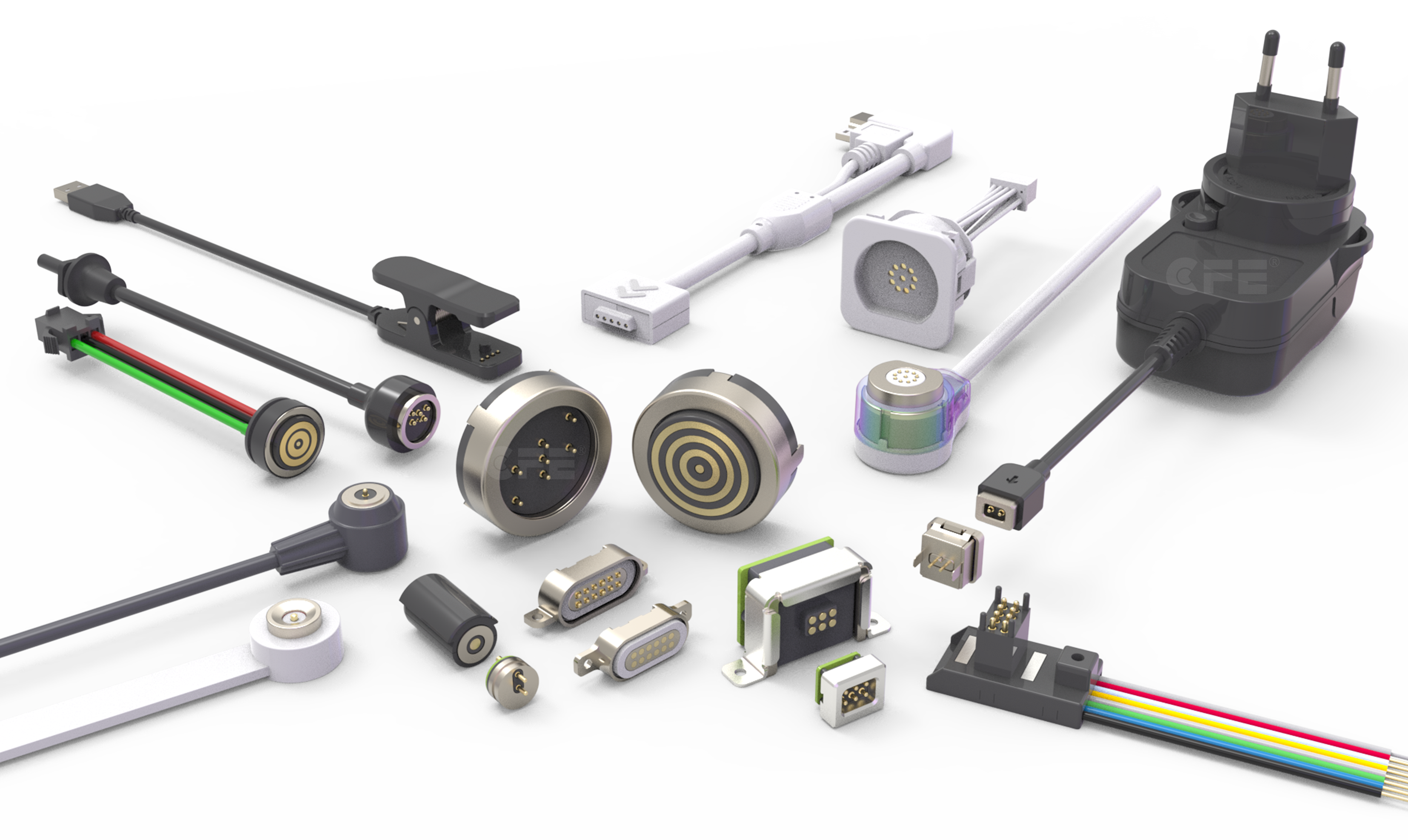

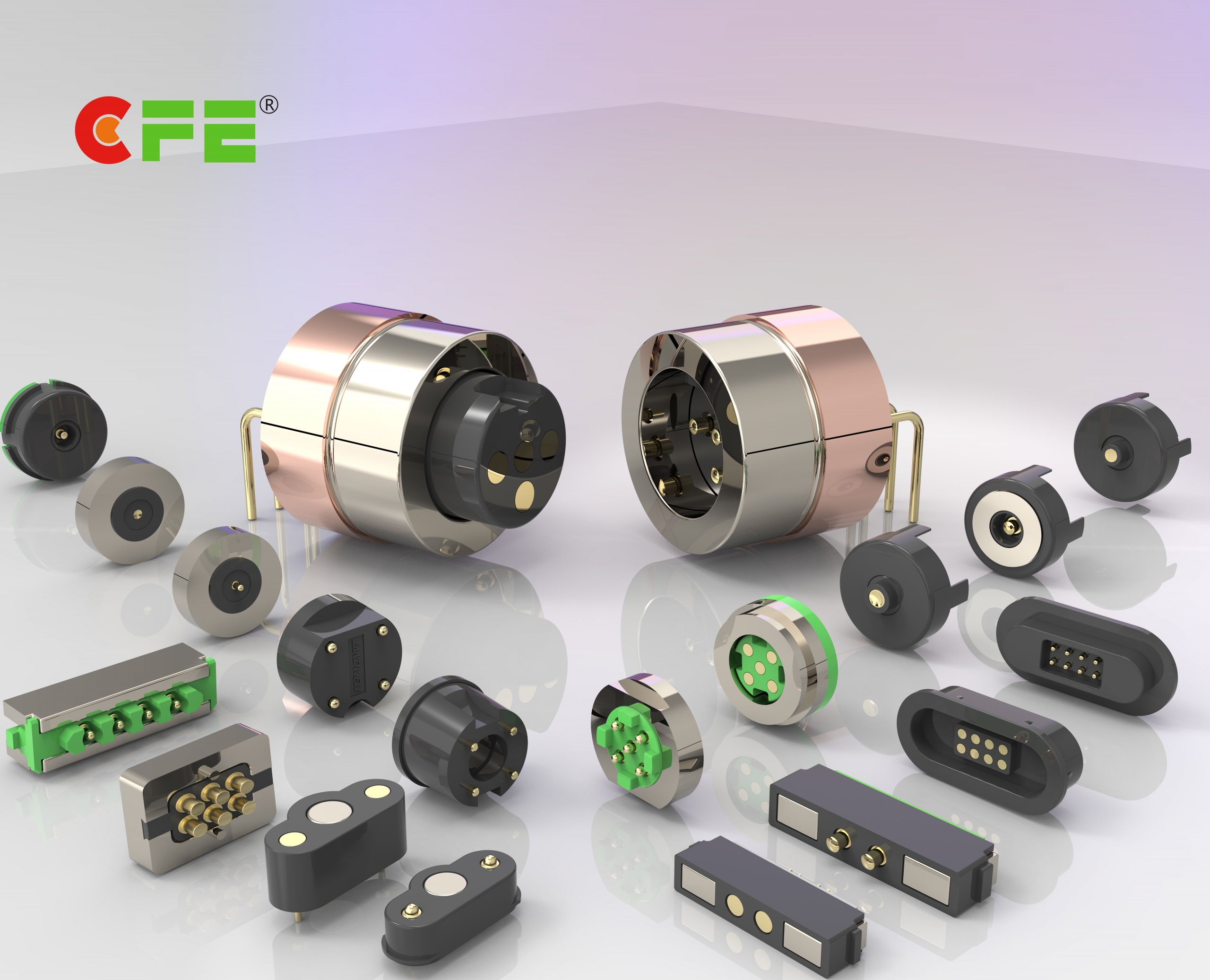

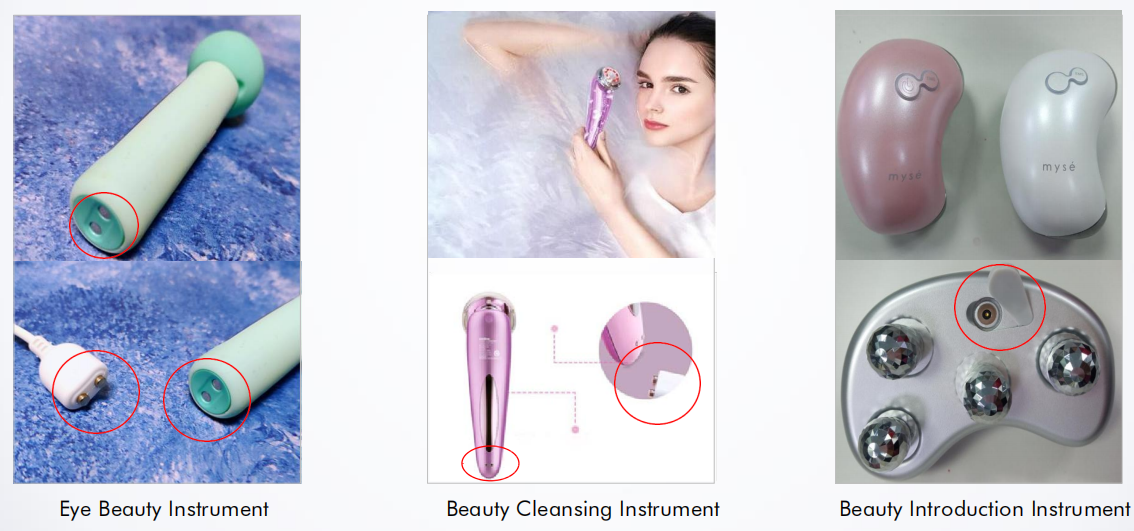

The composition of the pogo pin magnetic charging cable: the male and female ends of the magnetic connector. Usually the male end plus the cable part, or both ends with cable. A qualified pogo pin magnetic charging cable needs to pass a total of 17 tests. It includes mechanical, electrical, and environmental tests, etc.

At present, there are four common test specifications for magnetic charging cables on the market.

- MIL-STD-1344A (U.S. military specification – test method for electrical connectors)

- MIL-STD-202F (Test methods for electronic and electrical components)

- EIA-364 (American Electronics Industries Association-Electrical Connectors and Sockets Test Procedures)

- IEC-60512 (International Electrotechnical Commission – Connector Test Procedures)

And the magnetic charging cable produced by CFE Corporation must pass the following reliability test items.

- Mechanical performance test

It includes insertion force test, terminal and wire retention force, terminal and Housing retention force, durability test, swing test, lifting weight test, etc.

- Electrical performance test

Including insulation resistance test, withstand voltage test, continuity test, etc.

- Environmental performance test

Including salt spray test, constant temperature and humidity test, thermal shock test, high temperature life test, low temperature life test, high temperature and high humidity load test, low temperature load test, UV test, etc.

If the cable involves high frequency, it need to do SI test, and if it involves high voltage, it need to do high voltage related test. CFE always pursues environmental protection and compliance production, and its products include RoHS, HF, California 65, REACH, NP and other inspection report items.

If you need to know more about our magnetic products, please contact us immediately. CLE provides you with one-stop service!